Myford Super 7 Serial Number

Of this but you can date your lathe from the serial number - if memory serves on the tailstock end of the bed on the rear vertical face. 114516 = Super 7 1973.

XNoticeThis website or its third-party tools process personal data (e.g. Browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the.In case of sale of your personal information, you may opt out by sending us an email via our page.To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our.You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

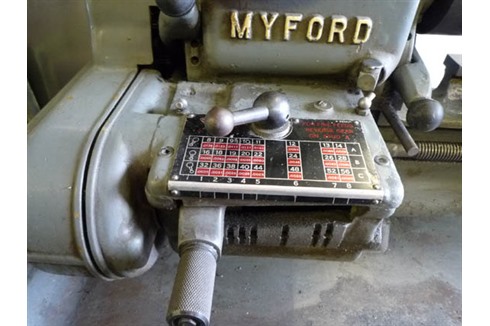

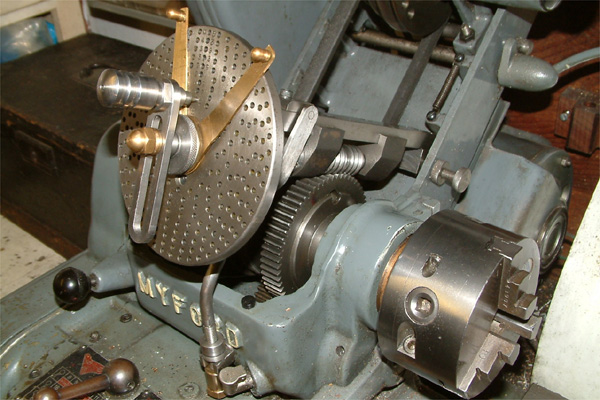

Hi All:A bit of a newb question here.The motor on our Myford Super 7 lathe has burned out and needs to be replaced; I'm not quite sure how to go about finding a suitable replacement. I've looked at the faceplate for the old motor (though I don't think this was the original motor) and tried to look up the model number or serial number without much luck. A photo of the info is attached.Is it simply a matter of matching RPM, HP, and frame (1725,0.5, and 56 in this case)? And does the frame dictate how the motor is mounted? In looking at pictures of frame 56 motors, it's not clear to me whether or not they would mount the same way on our lathe.Lastly, does anyone know the 'vital statistics' of the motor required for this lathe?

Lathes.co.uk seems to say that the Super 7 originally came with a 3/4 HP motor. Any recommendations from a fellow Super 7 owner on this?Thanks much.Rusty.

What you have there is essentially the perfect opportunity to put on a 3 phase motor and a VFD to give you a variable speed setup.Got an electric motor shop in your area? Go talk to them and see what the options look like.But, you are on the right track.

You need to look at frame size, as well as shaft diameter (if you wish to use the same pulley) as well as rotation direction.Pretty much any motor that fits, will do, but if you go with a TEFC motor, way less chance of the whole thing going electrically hot, from a chip getting in to the live circuits.CheersTrev. A TEFC 1hp 3 phase 1800 rpm motor driven with a VFD is optimal for an S7. Failing that a single phase TEFC 3/4hp 1800 will do.

If it's foot mounted it'll almost certainly fit, although the motor mounting plate can be modified easily with a drill. You may find that the shaft is the wrong diameter for the pulley you've got. It's better to discover this while you've still got a running motor for the lathe:eek. The original lathes were fitted with a resilient mount motor. That can make a significant difference to vibration from the drive belt. Four separate resilient mount feet made a detectable difference to my lathe.Mark Rand (VFD driven long-bed ML7B).

Window Media Center is the regular feature in Windows OS now. Windows XP Media Center. Windows Media Center Edition has come up in many versions and the one we are reviewing here is Windows XP Media center Edition 2005. Windows XP Media Center Edition 2005 was released on 12 th October, 2004 and it is. The 2005 version of Windows XP Media Center Edition! Includes Service Pack 3 because the ISO I have has SP3. Apparently the version of Windows and the version of Media Center are not the same. The Windows version is Windows XP Professional, version 2002. The Media Center version is 2005. How can I create a boot CD for Windows XP Media Center 2005 Edition? It's already installed, but I don't have a boot disc and plan on formatting the computer soon, I already have everything backed up, I just need to know how to create a boot CD. XP Media Center 2005 Edition, Restore or Boot Disk I have a Dell inspiron laptop and have installed linux on it. But since I was having the dell's system restore program running in the background there it hid windows from the linux installation and was deleted. Windows xp media center edition 2005 boot disk download - Best answers; Windows xp media center edition 2005 download - Best answers; Windows 8 media center download - How-To - Windows 8; Windows xp usb stick edition download - How-To - Windows XP; Windows XP - Bypass activation after a recovery or reinstalltion - How-To - Windows XP. Windows xp media center edition 2005 download boot disk.

I am fairly sure that you can buy a complete package deal of a VFD and suitable new 3 phase motor, with all required external switches pre-wired specifically for a Myford S7. The VFD even can come pre-programmed. It would make the replacement of your single phase motor with a much superior replacement very easy indeed. If you are interested I will look up some supplier details (UK). I'm not sure how UK domestic electrics (240V 50Hz single phase) will translate to US systems, but I doubt this will be a big problem unless you are limited to just 110V. You have many variables, that motor is single phase, going to assume you don't want to make replacement any harder or expensive then necessary, you could go up to 1HP on 110 with out much trouble.Pull the motor off measure the shaft.

And get one to match.What you want is a good continues duty motor, don't get some harbor freight import junk.An easy way to do it is take the motor with you to an industrial supplier and tell them what HP you want. I go to Kaman because they are close to me.There are specs for the motors in the catalogs. A good motor isn't cheap. Thanks all for the advice.

Seems like I was on the right track but it's coming in to focus better now.Mark Rand's suggestion (3ph + VFD) sounds appealing. Any recommendations on a supplier for a VFD or a VFD motor combo (ie help get a newb started on learning about this)?And picking up on the resilient mount issue, I'm finding single phase motors with a cradle mount, but no 3 phase motors with resilient mounts in this frame size. Is the 3 phase motor smooth enough, or can some kind of resilient mount be added?Thanks again!.

And picking up on the resilient mount issue, I'm finding single phase motors with a cradle mount, but no 3 phase motors with resilient mounts in this frame size. Is the 3 phase motor smooth enough, or can some kind of resilient mount be added?There is a good reason for that. Single phase motors produce a lot of vibration, three phase much less so. You should be OK with a standard mount, but resilient washers as feet would not do any harm.With a Myford S7, you presumably have a clutch. The cheaper Myford ML7s did not have a clutch as standard so the single phase motor would get started and stopped frequently. Even with a much smaller motor, there is a significant kick on starting.

A VFD gives you a nice smooth soft start which is nice for a lathe like this. For the benefit of someone who is unfamiliar with three phase and VFD controls: Several VFD makers (also called AC drives) make a VFD that will run a 220 V three phase motor of 1 HP or smaller off an ordinary 110 V household outlet. VFD's are very tolerant of voltage variations on both input and load. The motor can be rated from 208 to 240 and will still work OK.

I prefer to use a larger HP motor than originally called out for the machine when using a VFD. I also prefer a lower nameplate speed on the motor. I won't go into the reasons here, but I would look for a 3 phase 1 HP 240 V 1150 RPM motor and VFD to replace a 1/2 or 3/4 HP 1725 RPM single phase motor.As for source, I just watch eBay for low prices on motors and VFD's with the specs I want. I never paid anything close to retail.Possibly the old GE motor failed because it ate some chips. Single phase motors have exposed hot components inside around the centrifugal starting switch. That is why you need a TEFC motor around machine tools. Similarly, you have to keep chips out of the VFD.

Totally enclosed VFD's are scarce, but it is simple to enclose and cool them so chips will not get in.The 56 frame describes a certain set of mounting bolt dimensions on the base, the shaft height, and the 5/8' shaft diameter. You can find motor frame specs online. A larger motor, like 1 HP, and a slower motor, like 1150 RPM, will probably have a larger frame with 7/8' shaft. Mounting holes can be drilled and pulleys can be bored or shafts turned, but watch out for shaft height.Larry. Mark Rand's suggestion (3ph + VFD) sounds appealing. Any recommendations on a supplier for a VFD or a VFD motor combo (ie help get a newb started on learning about this)?Read up here on the forum there is lots of good info here. However you can read till you pass out its just one of those thing you need to do to completely understand your particular VFD.

I recommend buying something brand name (Teco, HITACHI etc) and you can be sure someone here has already setup one up.Two recommendations for suppliers. There have been many useful replies to this question, but I'd like to add that I converted a Myford Super 7 to a 3-phase motor with VFD, and it went very smoothly (both the conversion job and the lathe running afterward). IIRC, a 56 frame 3/4 hp motor went on without adapters or funny hardware. At the time (about 10 years ago) lots of new, or nearly new, 3-phase motors could be found on ebay for under $100 with shipping.

I don't know if that's still the case, but it's worth checking. 3/4 HP is very common.

Download hanuman amritwani anuradha paudwal. For home use, even a 1/2 HP 3-phase motor would probably seem just as robust as your old single phase motor.I'll only add one thing about VFDs, some of the older models have very low chopping frequencies (like around 5kHz) which means they can make the motor 'sing'. I found this annoying on my first VFD, so then I got a small TECO, that chopped around 12-15KHz, and that was much quieter.

- суббота 28 марта

- 76